Innovative insulation solutions from the pioneer of insulation technology

Discover va-Q-tec’s pioneering solutions for sustainable and energy-efficient construction, electric vehicles, refrigerated transportation, household appliances, pipelines, and hot water tanks. Our vacuum insulation panels not only deliver maximum thermal insulation performance but also facilitate a substantial reduction in energy consumption. Through tailor-made system solutions, we contribute to environmental and climate protection and assist in efficiently managing your energy requirements. We would be delighted to convince you of our quality philosophy and the sustainability of our products.

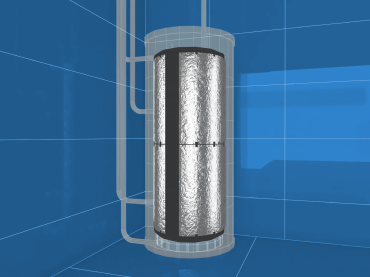

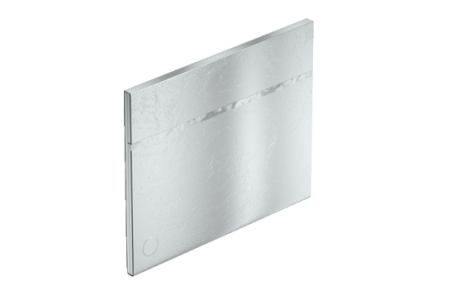

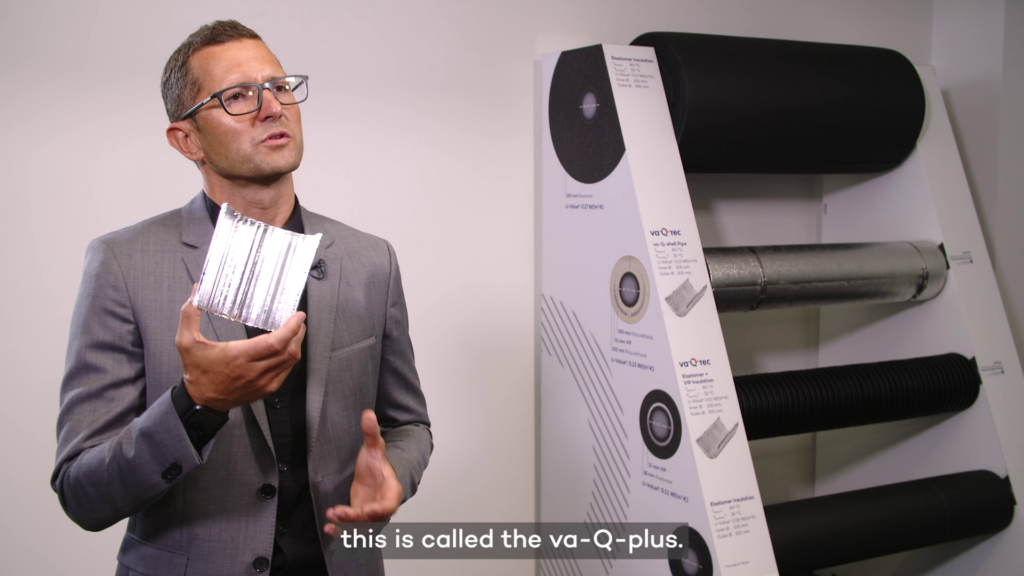

Hot Water Tank

Vacuum insulation panels: the key to energy reduction and climate protection in the heating sector

The emphasis on environmental and climate protection has increased significantly, driven by the urgency to find solutions to curb global warming. Our approach focuses on highly efficient thermal insulation, particularly with vacuum insulation panels. These panels can reduce the energy consumption of hot water storage tanks by over 50%. In industrialized countries, the energy demand for thermal processes accounts for over 55%, and in private households, it is even 75%, primarily due to heating and hot water preparation. Efficient thermal insulation is especially crucial in heating systems and hot water storage tanks, which is why the EU has introduced the energy efficiency label to make sustainability and environmental friendliness transparent for end consumers. We would be delighted to convince you of our quality philosophy and the sustainability of our products.

Advantages of VIPs

Options for insulation

Energy efficiency

Sustainability

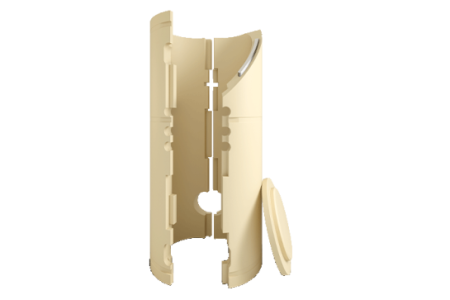

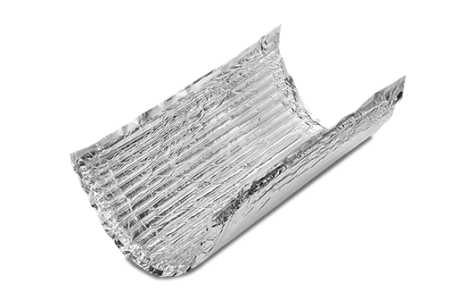

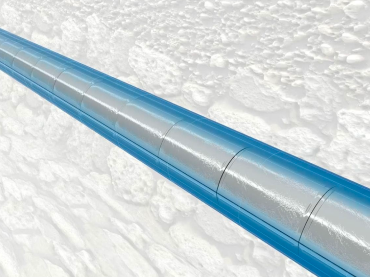

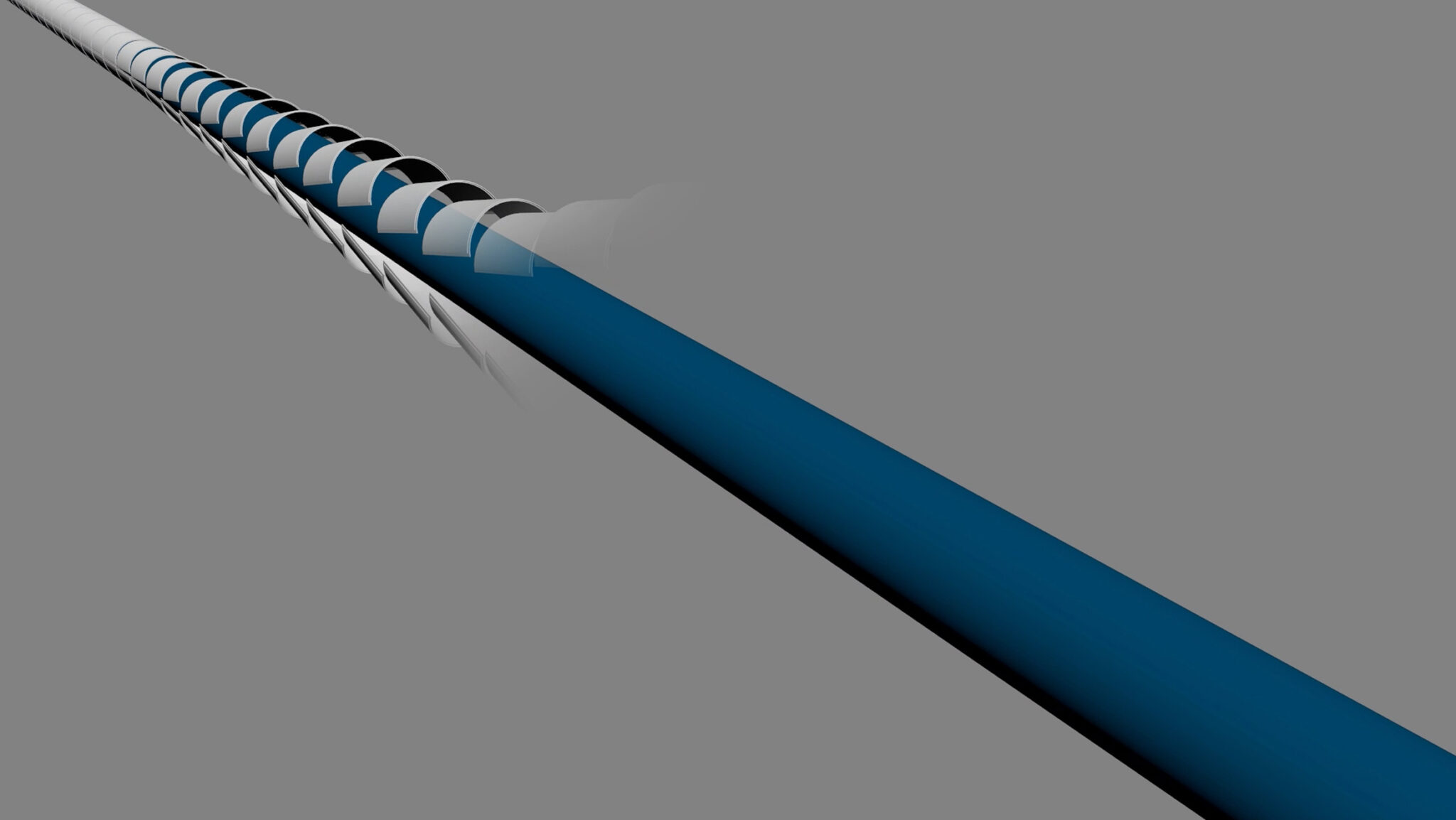

Piping

The solution for highly energy-efficient pipelines

va-Q-tec’s thermal insulation performance enables high efficiency with the same or even lower insulation thickness, reducing energy loss by more than 50%. Ready-made system solutions are available, including options for retrofitting. Our solutions are suitable for a wide range of applications, such as local and district heating, process media, oil and gas production, and the chemical industry. These solutions range from integrating vacuum insulation panels (VIP) into existing thermal insulation concepts to providing complete system solutions for retrofitting insulation to pipelines. We would be delighted to convince you of our quality philosophy and the sustainability of our products.

How does it work

Used VIPs

Sustainability

Effects & energy losses

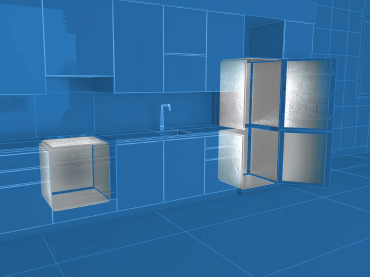

Insulation solutions in household appliances

Your expert for insulating refrigerators and freezers

va-Q-tec is one of the world market leaders for vacuum insulation panels (VIPs) in the refrigerator and freezer market. Space-saving and highly efficient VIPs from va-Q-tec form the basis for simple and very effective energy-saving measures in this sector. Modern and innovative vacuum insulation panels with specially developed silica powder as the core material achieve a particularly long service life of up to 50 years. We would be pleased to demonstrate our commitment to quality and the sustainability of our products. We would be delighted to convince you of our quality philosophy and the sustainability of our products.

VIPs and differences to conventional insulation

Suitable Areas for VIP

Energy Efficiency

Sustainability

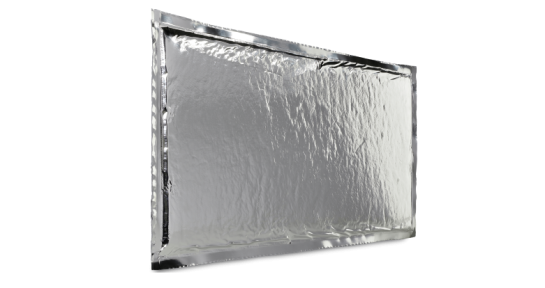

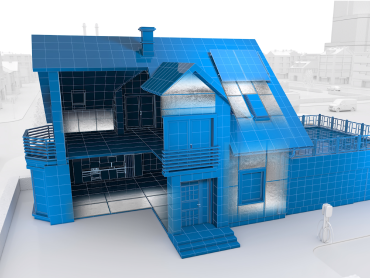

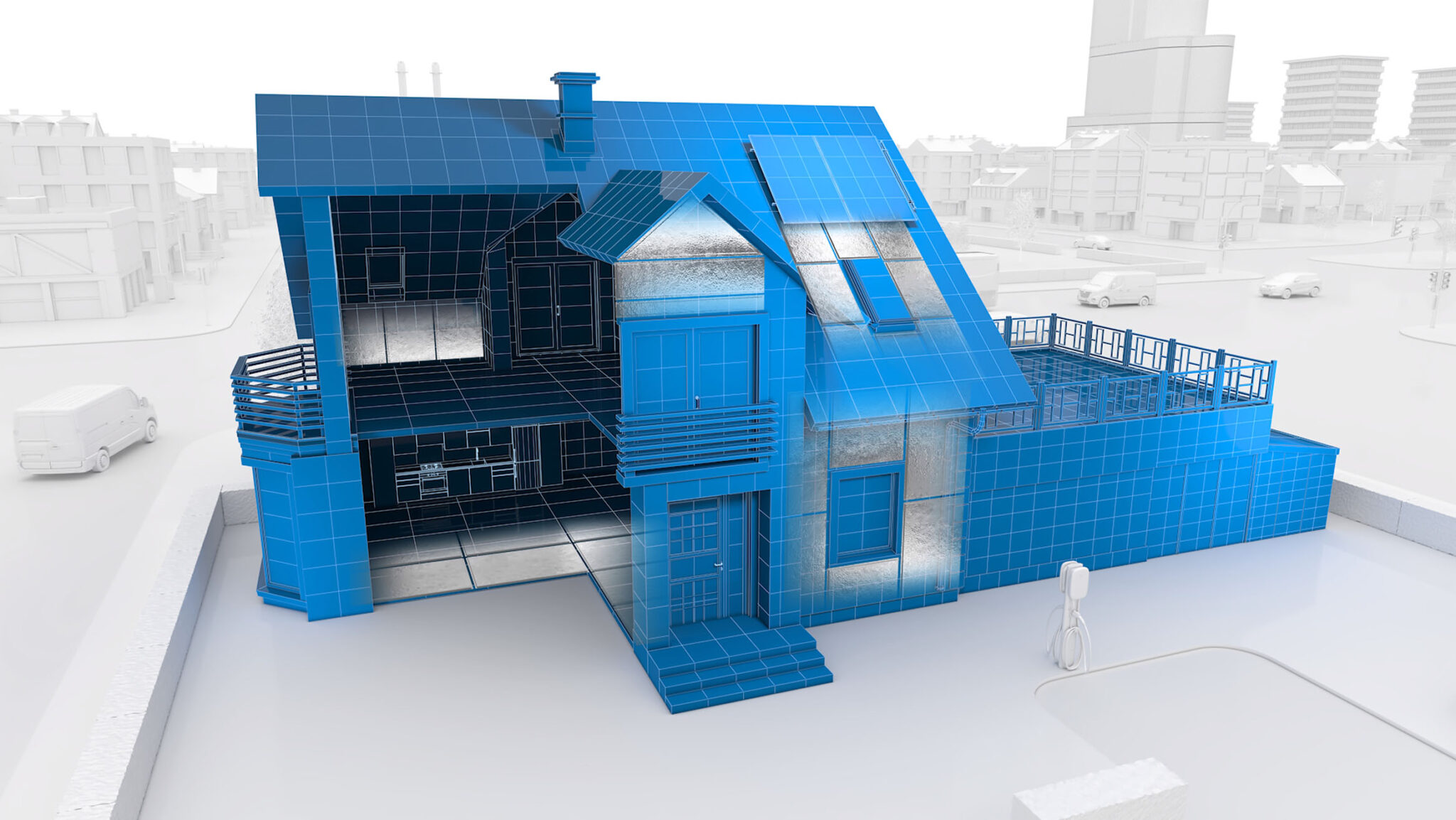

Insulation solutions in buildings

More usable space and less energy consumption thanks to vacuum insulation

In unrenovated houses, a third of the heat from heating is escapes through the exterior walls. Comparing the heat loss of unrenovated buildings with houses whose facades have been insulated with vacuum insulation panels, the reduction in heat loss is significant. With efficient insulation, it is important that surfaces are fully insulated. Vacuum insulation panels excel in minimizing energy loss, even in tight spaces, due to their low thermal conductivity and minimal material thickness. If just ten percent of the insulated areas of single-family homes were insulated with vacuum insulation, Germany could save 200,000 tanker loads of heating oil every year. Vacuum insulation proves especially beneficial in buildings where space is scarce or expensive. We would be delighted to convince you of our quality philosophy and the sustainability of our products.

How does it work

Comparison conventional vs VIPs

Application Examples

Sustainability

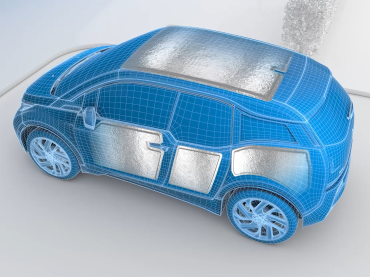

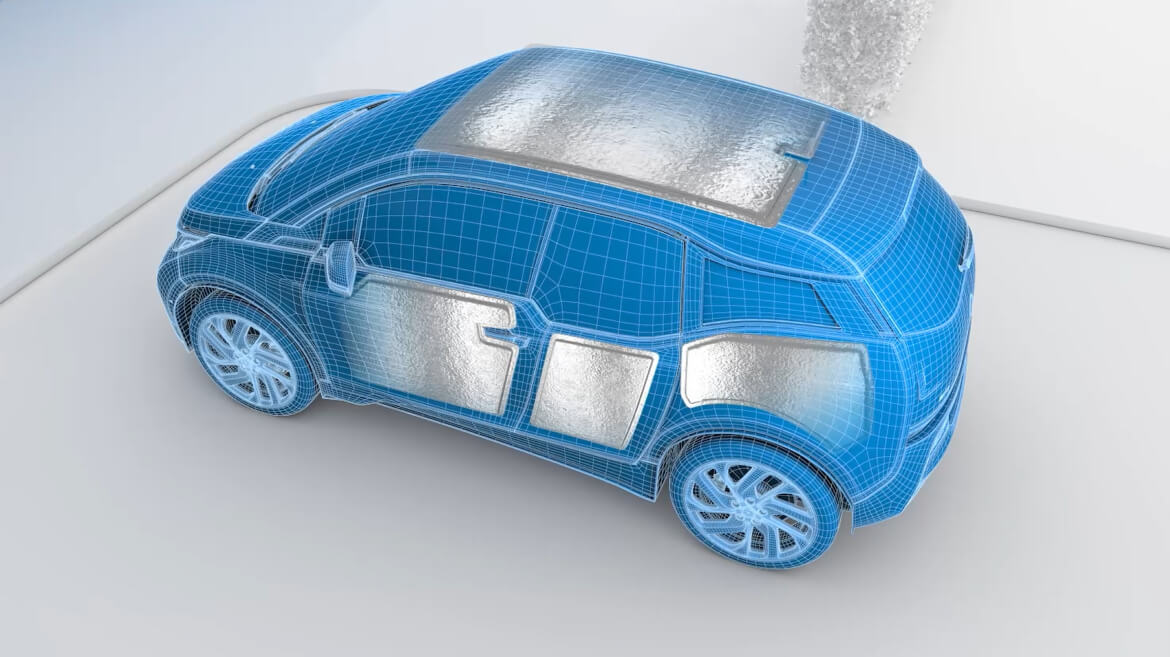

Electric car

Automobile Industry

The increasing use of electric vehicles has revealed that extreme ambient temperatures significantly reduce driving range. By employing va-Q-tec’s VIPs, a significant improvement was achieved in an internal project involving a BMW i3. These VIPs improve battery performance, climate comfort, and range by compensating for temperature fluctuations and reducing the need for air conditioning. The result: reduced energy consumption, and increased range. The optimization of the insulation demonstrates that electric vehicles equipped with high-performance insulation can become more energy-efficient and durable. We would be delighted to convince you of our quality philosophy and the sustainability of our products.

How does it work

Areas

Range & Comfort

Significant potential

Refrigerated truck

Vacuum insulation panels in commercial vehicles

va-Q-tec’s vacuum insulation panels are highly efficient insulation materials for refrigerated vehicles, providing up to 10 times better insulation than conventional materials. They offer flexibility in terms of thickness and shape making them ideal for use even in limited spaces. In a project with Brandt Kühlfahrzeuge, the optimal material properties of these panels became evident: they enable significant energy savings and CO2 reductions. In addition to the ecological benefits, they are cost-efficient, as the additional costs for the improved insulation are quickly amortized. We would be delighted to convince you of our quality philosophy and the sustainability of our products.

How does it work

VIP & conventional

Range

Sustainability