Technics & Industry

High-quality insulation for industrial applications

va-Q-tec is a pioneer in the field of vacuum insulation in the industry. We develop advanced insulation solutions for a wide range of industrial applications. Our innovative products minimise energy loss, make processes more efficient and reduce operating costs. va-Q-tec offers specially developed solutions that meet the highest requirements while also helping to reduce the ecological footprint.

Optimal insulation solutions for industrial challenges

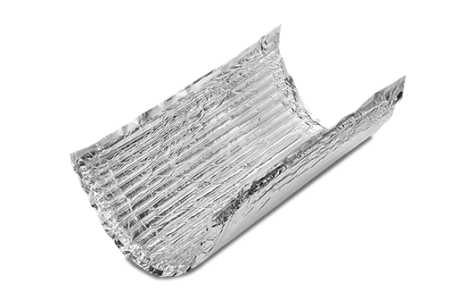

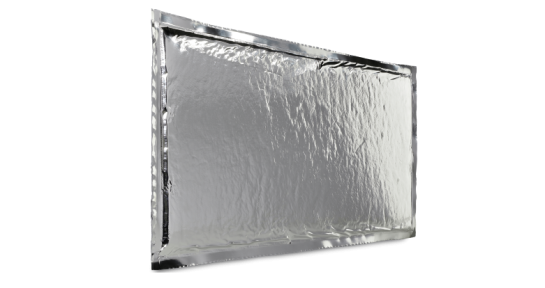

In industry, efficient insulation solutions not only serve to reduce energy loss, but also ensure the safety and longevity of equipment. Vacuum insulation panels (VIPs) are at the heart of our company’s technology. These are the basis for various products that are characterised by their exceptional insulation performance combined with very low material thicknesses.

va-Q-tec’s insulation solutions for the industrial sector are particularly advantageous when space is limited but high thermal insulation is required. Compared to conventional insulation materials, VIPs offer up to ten times better performance.

The high quality of our products is guaranteed by the unique va-Q-check® system. This ensures reliable application of the durable and highly efficient vacuum insulation.

Products

Vacuum Insulation Panels

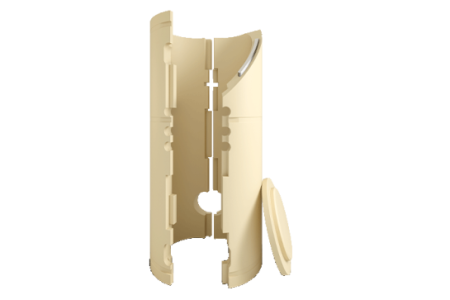

System solutions

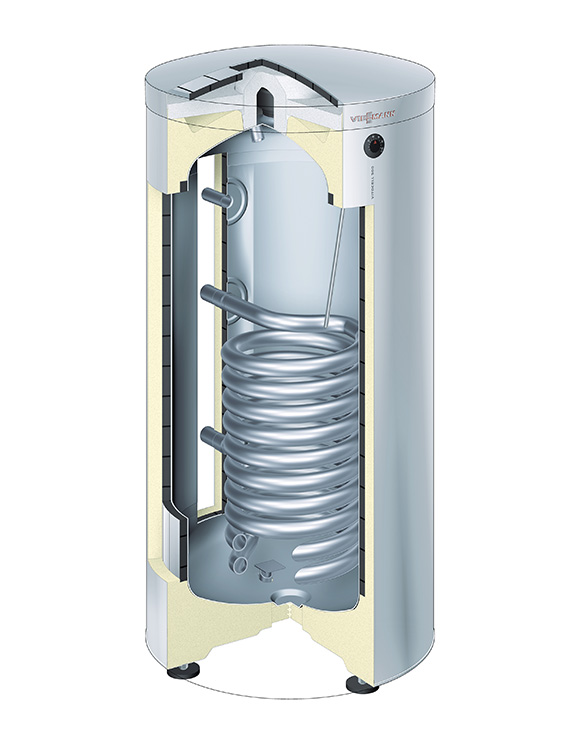

Applications for industrial insulation

At va-Q-tec, we offer a wide range of solutions for various industrial sectors. In hot water storage tank technology, for example, vacuum insulation improves efficiency by significantly reducing heat loss. In piping systems VIPs provide reliable insulation for valves, pipes and tanks, which not only saves energy but also contributes to the longevity of the equipment.

In addition, our industrial insulation is used in laboratory equipment such as incubators, where highly precise temperature control is required. In these cases, our products ensure constant temperatures and high industrial energy efficiency. At va-Q-tec, we also offer customised solutions for specific challenges.

Pipeline insulation

Industrial plants often have extensive pipeline systems that need to be thermally insulated. va-Q-tec’s copper pipe insulation and water pipe insulation systems are highly efficient. They minimise heat loss and are a reliable choice for protection against frost damage.

Insulation for high temperature applications

For industries that work with high temperatures, va-Q-tec offers heat-resistant insulation that can withstand extreme conditions. These are ideal for use in heating and power plant applications.

Ventilation and air conditioning

Efficient insulation for industrial ventilation pipes plays a key role in modern buildings and facilities. It prevents heat loss and helps to reduce the operating costs of HVAC (heating, ventilation, air conditioning) systems.

Insulation of industrial facilities

Complex facilities, such as production lines or specialised technical systems, require precisely tailored insulation solutions. va-Q-tec relies on customised systems that are specifically designed to meet the needs of industrial facilities.

Advantages of va-Q-tec insulation for industry

va-Q-tec vacuum insulation offers many advantages: It helps to reduce energy consumption and CO2 emissions, providing a sustainable solution for companies seeking to reduce their environmental footprint. In addition, the products increase cost efficiency by significantly reducing energy consumption over the long term. The long service life of the VIPs and their resistance to extreme conditions ensure that they work reliably even in the most demanding circumstances. In addition, the minimal insulation thickness saves valuable space, which is particularly advantageous in compact industrial environments.

Services for Technics & Industry

Examples of industrial insulation applications

A consultation with our experts will help you find the ideal solution for your individual needs. The following examples of applications already give you an overview of the possibilities with our insulation technology in the industrial sector.

Further insulation solutions from va-Q-tec

In addition to building insulation, va-Q-tec also develops solutions for other industries. These include the construction industry, but also the last-mile pharmaceutical logistics, with special packaging for temperature-sensitive drugs. The mobility industry also benefits from our technologies. In the food sector, our insulation techniques ensure that goods reach their destination at the ideal temperature.

Find out more about our offers!