Piping

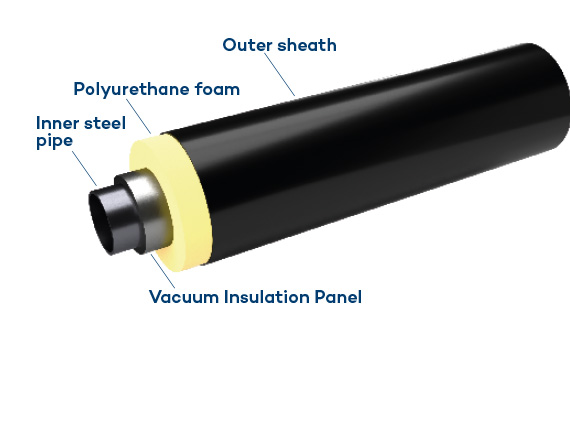

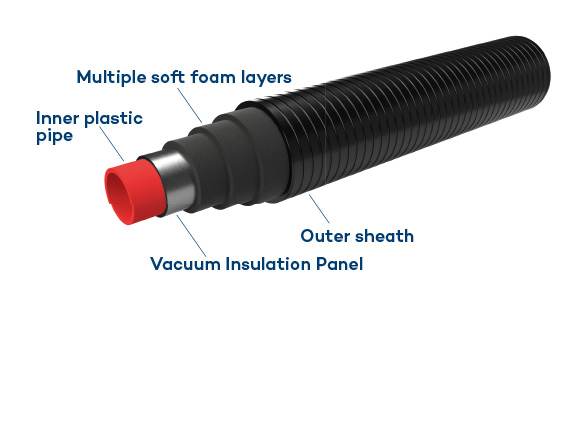

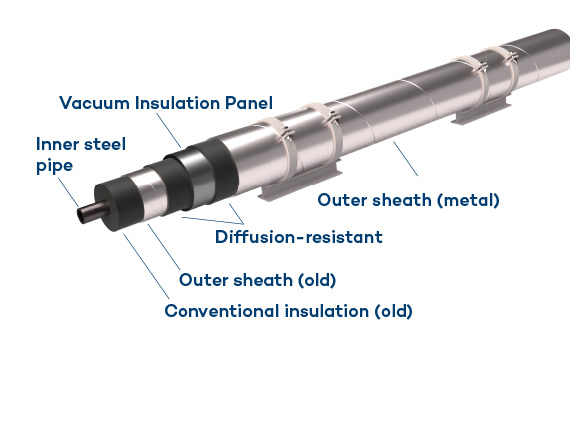

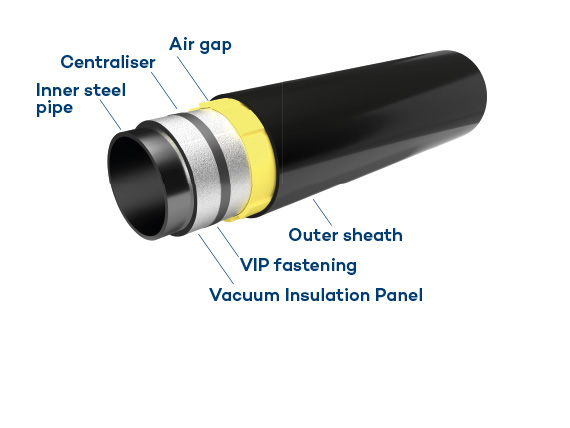

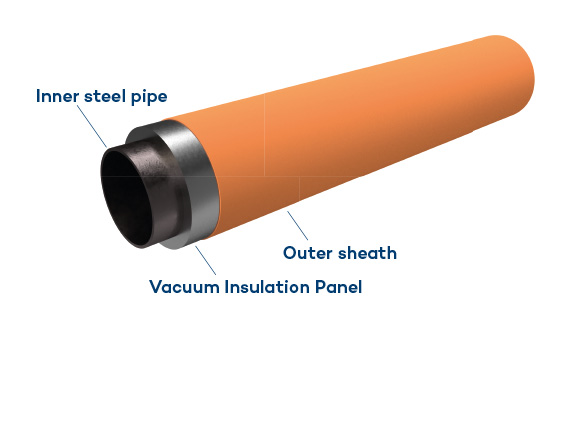

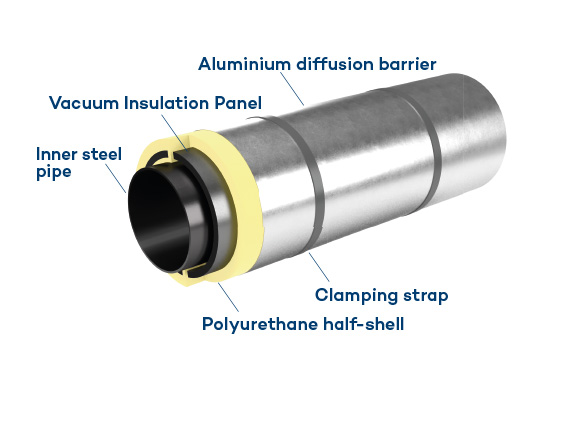

We offer a large range of highly efficient thermal insulation solutions for many applications and pipes of almost all types. The basis for these system solutions is formed by the related VIPs with their low thermal conductance figures. These panels are integrated into an overall solution that meets the varying geometric, thermal and technical requirements for the related type of application.

Together, all these system solutions have excellent thermal insulation performance but nevertheless with thin insulation. In this way the pipe losses can be reduced by up to 50% or even more compared with conventional pipe systems. The slender structure also means less space is required on-site. As a complete system, valuable time can also be saved during installation.