Home / Technology / Quality Control System

Quality Control System

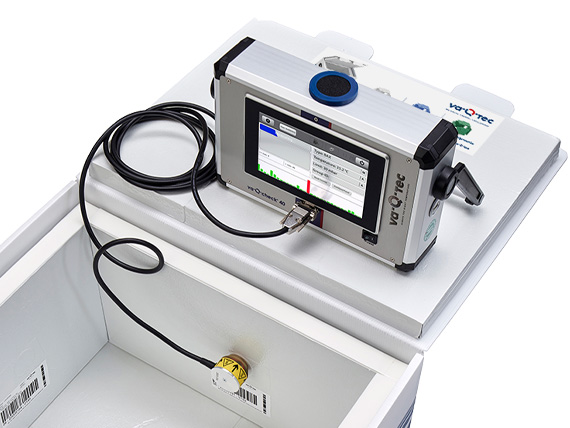

Control System of va-Q-tec

Quality lies at the core of everything we do at va-Q-tec – the capital „Q“ in the middle of our name serves as a reminder hereo. In addition to premium quality service and wellfounded technical consulting, we strive to produce only the very best quality products.

Quick and precise quality checks

Lifetime performance of the VIP

Advantages of va-Q-check

Quick and precise quality control

Significant reduction of non-visible VIP defects

Vacuum check by customer possible