Technology

With our advanced passive technology & expertise, we provide our clients with cost-efficent, safe and green thermal packaging.

– Dr. Joachim Kuhn, Founder & CEO

Vacuum Insulation Panels (VIPs) are used wherever space is limited and excellent thermal insulation is required. va-Q-tec has been pioneering the field since 2001 to help resolve difficult spatial design problems, and offers a range of products including cost-effective customized VIPs and heat & cold storage elements containing Phase Change Materials (PCMs).

The temperature-controlled logistics field requires everyone to stay updated and innovative to comply with the latest regulations and demands. va-Q-tec created the term “TempChain” to replace “cold chain” to encompass all areas and temperature ranges of temperature-controlled logistics regardless of the environment and outside temperature.

Why va-Q-tec

VIPs maintain the defined temperature

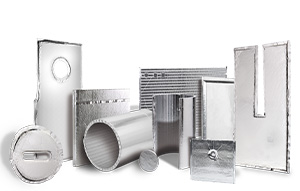

VIPs – Vacuum Insulation Panels – are flat panels for optimized temperature insulation that are based on the principle of the thermos flask. These panels offer unparalleled heat and cold insulation at minimum thickness.

va-Q-accus define the temperature

Phase Change Material (PCM) accumulates and releases thermal energy during melting and freezing, to perfectly maintain the required product storage temperature for the duration of transportation.

Qualified High-Performance Packaging

As a core component manufacturer, we design and produce products with state of the art solutions and many economic and ecological advantages, such as recycling possibilities and superior quality with an excellent price/performance ratio. Our products are designed with one packout configuration for all seasons that simplifies handling and reduces risk.They are validated to strict standards to ensure a safe transportationcycle for many days.