Application Examples for Mobility

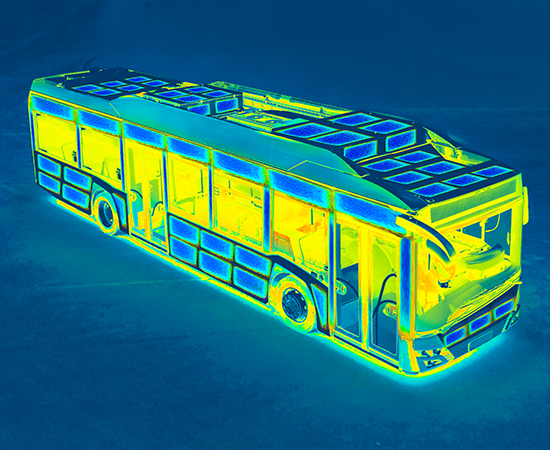

The manufacture of industrial products is becoming more and more complex. The demands on applied materials are constantly increasing. Our innovative products and solutions meet and even exceed all those demands due to their disruptive technology. By installing our products, highest requirements on energy efficiency and environmental protection are fulfilled as well as our clients’ needs for comfort and safety. Our solutions meet the highest quality standards through standardized production processes and the use of the patented va-Q-check® system. With our new fire protection development all our solutions can withstand the most critical fire protection requirements such as in the aviation (AITM), the railway (HL3) and other industries.