Case Study BINDER

Challenge

The continuous internal temperature of approx. -86 °C requires high energy usage. Standard insulation materials are thick and occupy valuable internal space or contribute to an increased total volume.

Solution

By means of the use of VIPs on all six sides, thinner walls are made possible and the energy consumption reduced at the same time. In this way no condensation forms on the outer casing.

Support during Corona vaccine research

Along with support to global, life-saving medicine logistics for Corona test kits, with its unique vacuum insulation panels (VIPs) va-Q-tec is also supporting the German laboratory equipment manufacturer BINDER whose equipment is considered imperative for Corona research. In this way va-Q-tec is actively contributing to fighting the virus also in this area.

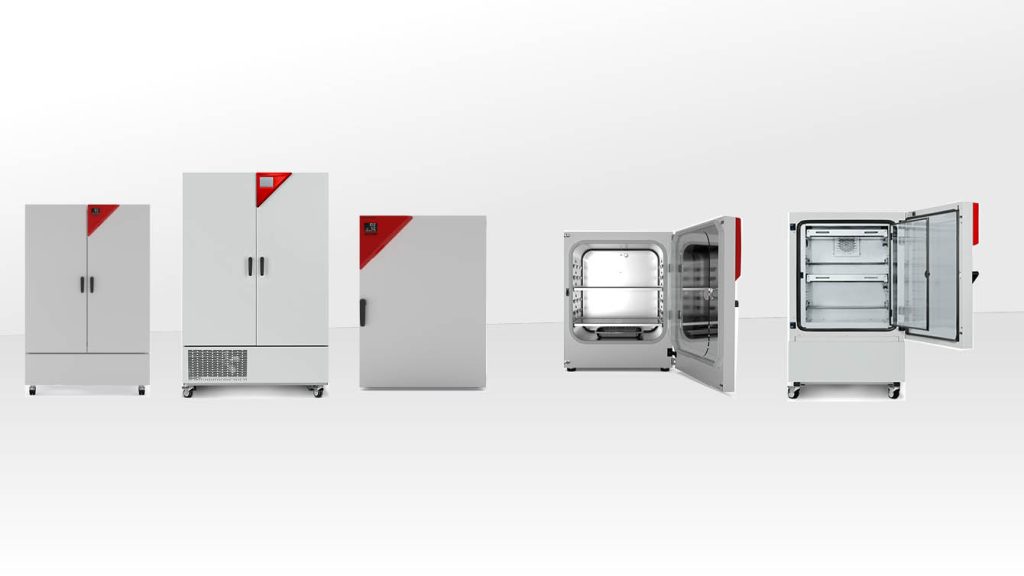

va-Q-tec Thermal Solutions GmbH has collaborated with BINDER GmbH for many years. However, in times of the Corona crisis, the system relevance of this co-operation has become clear: to find a suitable vaccine or remedy for the pathogen, the pathogen must be produced synthetically. The breakthrough in the synthetic reproduction of the virus was achieved by a research team at the University of Bern (Switzerland) with the aid of BINDER ultra-low temperature deep freezers.

These laboratory appliances must sustainably and reliably maintain temperatures lower than -86 °C. These temperature retention characteristics can be guaranteed by fitting va-Q-tec’s vacuum insulation panels (VIPs) in an energy and cost-efficient manner. Due to the ten-times better insulation than conventional insulation materials, the panels make it possible to manufacture freezers with thinner walls. As a consequence the internal volume of the appliance increases and more samples can be placed in it.