Home / Business Areas / Appliances

Appliances

Your Experts for Insulating Refrigerators and Freezers

va-Q-tec is one of the global market leaders for vacuum insulation panels (VIPs) in the refrigerator and freezer market. Space saving and highly efficient VIPs from va-Q-tec form the basis for simple and very efficient energy saving measures in this field.

Modern and innovative vacuum insulation panels with specially developed silica powder as the core material achieve a particularly long service life of up to 50 years. We would like to convince you of our quality philosophy and the sustainability of our products.

Products

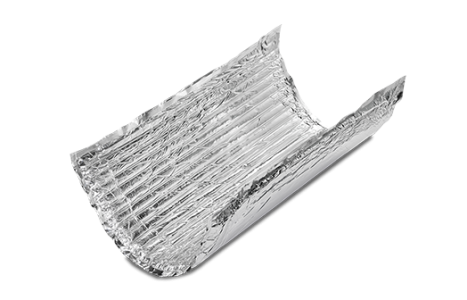

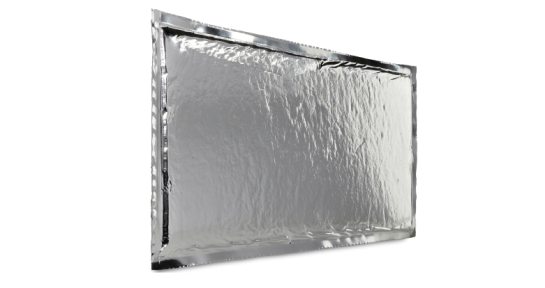

Vacuum Insulation Panels

Advantages

More usable volume and lower temperature losses

Best possible temperature balance and and avoiding condensation effects

Complying with new energy legislation

Reduced energy consumption and reduction of carbon footprint

Long service life of va-Q-tec VIPs

Reaching high energy efficiency classes